About Calcium Carbonate

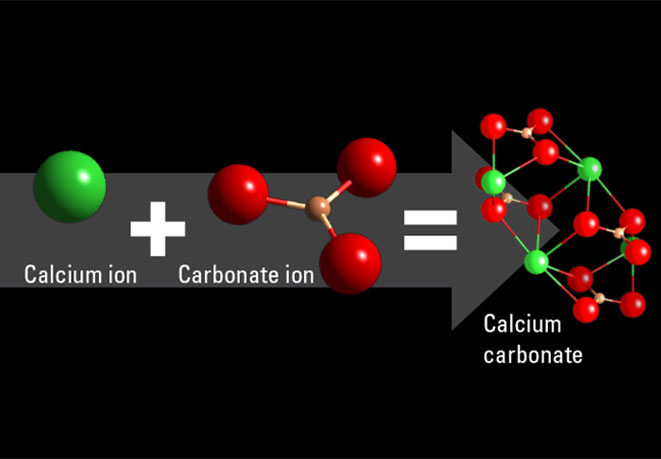

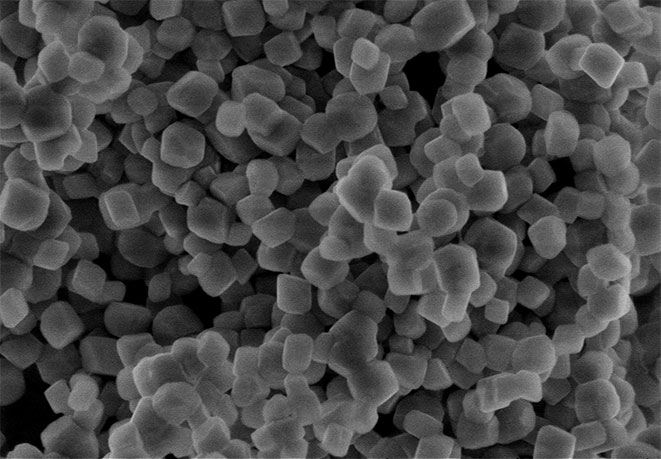

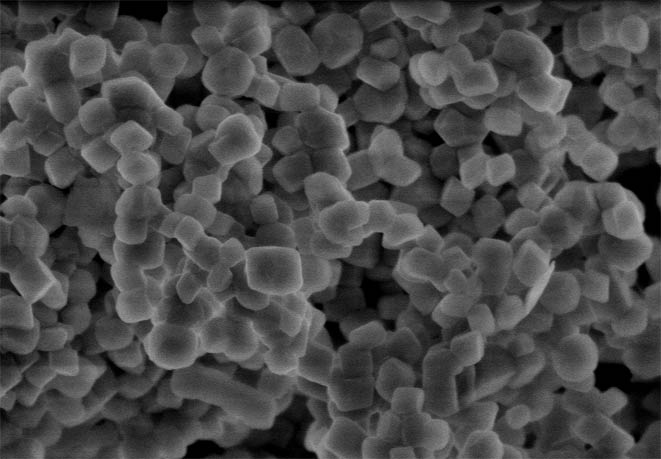

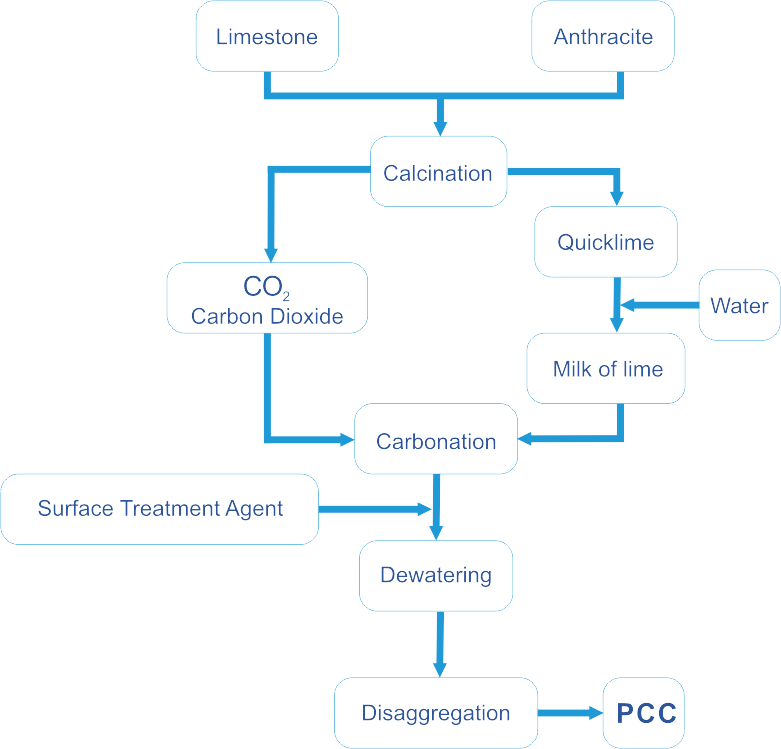

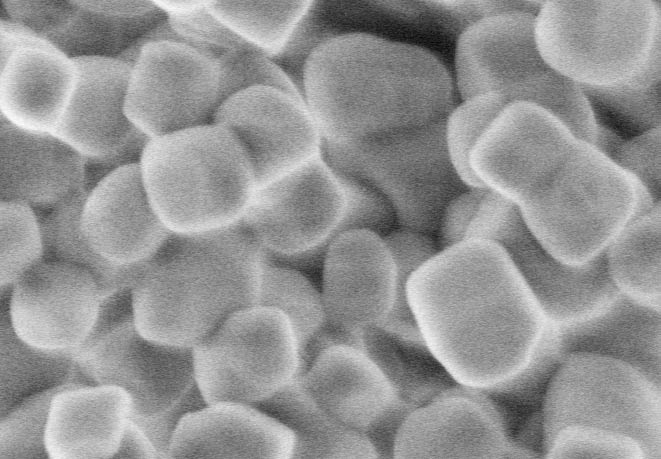

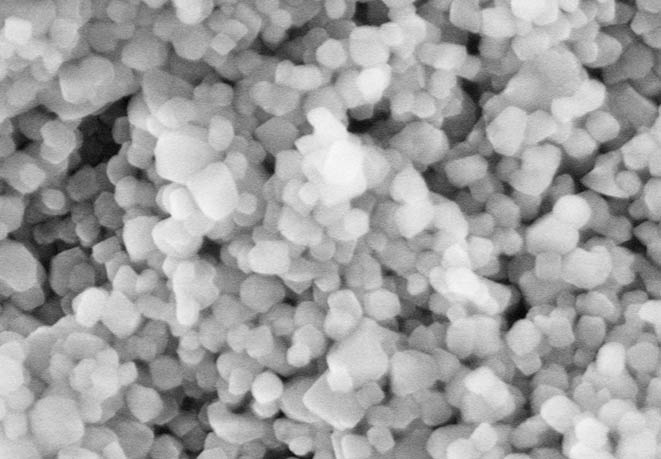

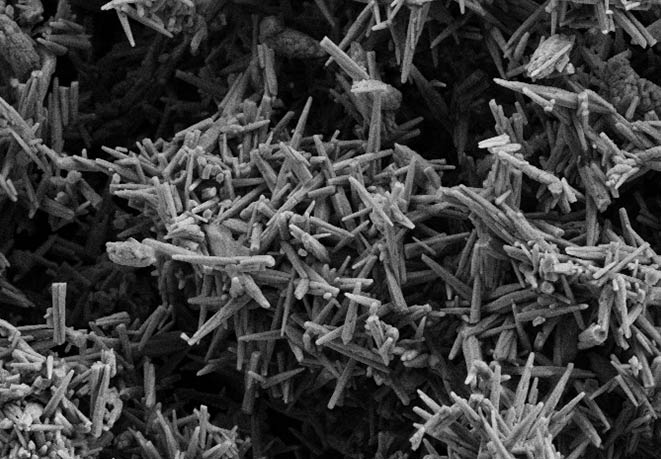

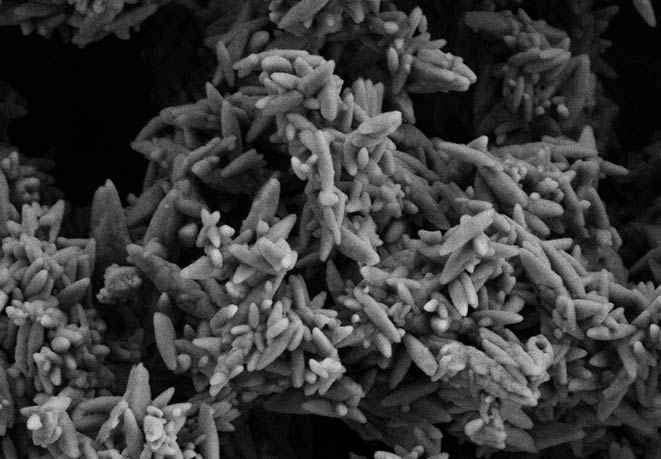

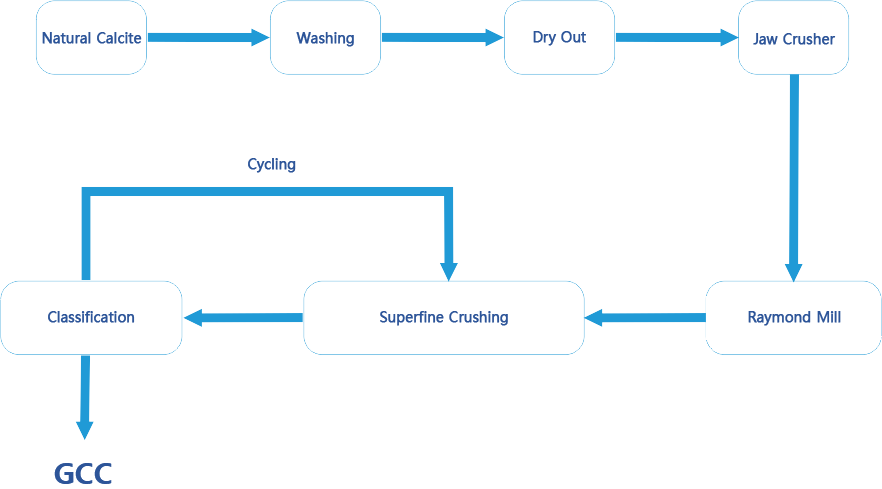

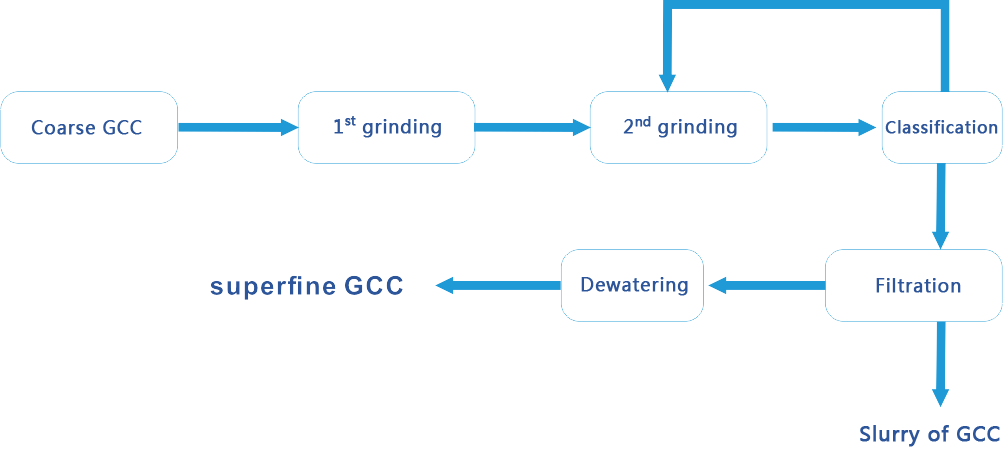

Calcium Carbonate is a compound with the formula CaCO3, the major component of limestone. In nature this occurs as a mineral found in three distinct crystalline structures, ie. calcite, aragonite and vaterite, these are special phases relate to the arrangement of the atoms in the crystal structure. And these distinct phases influence the shape and symmetry of the crystals. Industrial calcium carbonate is a semifunctional mineral filler including precipitated calcium carbonate (PCC) and ground calcium carbonate (GCC). PCC is obtained by a chemical reaction, while GCC is made by mills. The main advantage of PCC compared with GCC is resulting products can be controlled by certain parameters of the chemical reaction. GuangXi Huana products calcite or aragonite crystals PCC in different shapes: rhombohedral (quasi-cubic), ditrigonal scalenohedral, rose-like, prismatic, rod-like and rice-like. Vaterite is not stable and over time will transform into the other two crystal. While GCC is calcite.

Calcium carbonate has a wide variety of application such as rubber, plastics, sealant, construction, paper, paint and ink et al. GuangXi Huana specializes in the studying and manufacturing PCC and GCC with particle size ranging from 0.03 microns to 15.00 microns.